Support us on Patreon: https://www.patreon.com/woodshoplife

Guy

1) Hey guys! I love the pod cast, ya’ll really do a great job. My question is about radial arm saws. I have recently started selling tables on the side to try and make some extra cash. Right now I do pretty much all my cross cuts with my 10″ Chicago Electric miter saw and I am tired of having to flip over anything wider then a 2×4 to cross cut. It seams that these radial arm saws are a dime a dozen on the market place apps and can be bought pretty cheap. How do they stack up to a sliding miter saw? I’ve really been thinking about giving one a shot just based on the $75 price tag. – Jimmy

2) Another question for you all. Every power tool I own seems to come with it’s own set of tools – allen wrenches, different heads, attachments, maybe a spare cutter or bolt, etc. How do you organize these ‘spare parts’ in your shops to keep them handy when you need them, and help identify which of these things belong to which tools? Attach them to the tool somehow (with string? duct tape? magnets?) With hand power tools, keep the paraphernalia with the tool?

The Ziploc bag method I’m using now seems so gauche. thanks for the great show Mark mlbettwoodworks

Sean

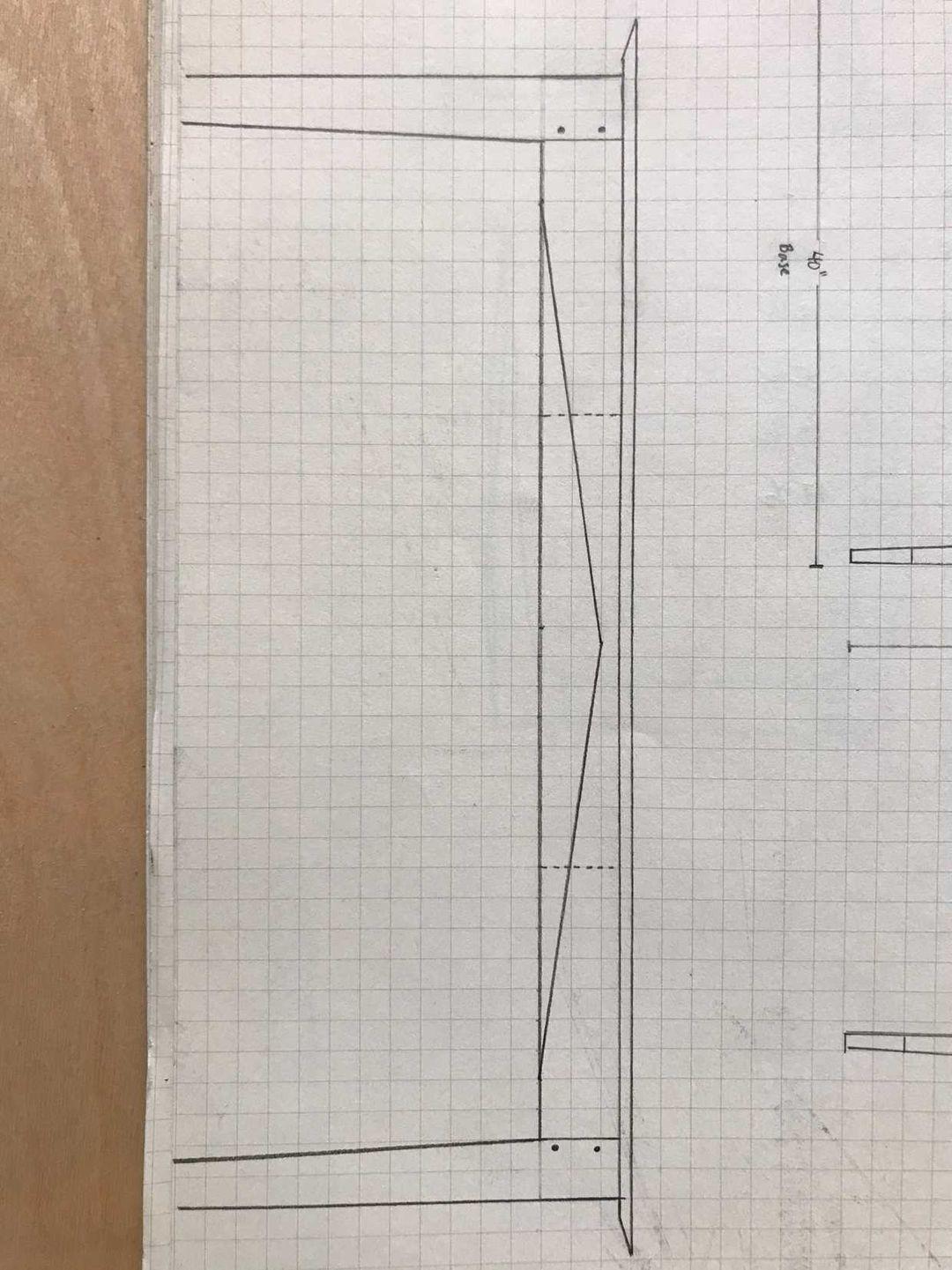

1)In a recent episode you discussed laminating two pieces of hardwood together and the need to offset grain directions to avoid warping. I’m building a simple, traditional writing desk (with a modern flare) and my plan is to accent the air dried walnut drawer fronts (5/8” thick) with an 1/8” piece of curly maple. I’ll be routing out the section to receive the maple taking the walnut thickness to about 3/8”. My plan at that point was to laminate the maple into place.

Is this a situation where I should be concerned about movement? Do you think the lack of material thickness will minimize these potential issues? Any advice or input would be helpful. I have sent a sketch photo to your IG page for reference. Cheers, Taylor (not Tyler)

2) I recently completed a build for two white oak desktops and, in my excitement to see how the grain would pop and without considering the ramifications of my actions, I threw on some mineral oil. Man, those desktops looked BEAUTIFUL. After applying just one coat, I realized I should’ve done some research. I’m still learning about finishing techniques and figured I could use mineral oil the same way as mineral spirits in this context. I quickly realized the gigantic mistake I had made. After spending some time on a few woodworking forums, it became clear that there’s really nothing to do but lean into finishing these desktops with more coats of oil as no other finishes will properly adhere. However, I have seen some comments mentioning shellac as a possible option since shellac and mineral oil are used in combination for French polishing. This is not necessarily the look I’m going for but I’m wondering what you’d advise in this situation.

PS I’d really like to avoid sanding it all down again. And its 10 degrees outside so I’m limited in chemical options if I have to open the garage doors for ventilation.

Thank you guys for all you do. This podcast is always a huge help!

Christina

Huy

1)I currently have my bandsaw (Rikon 10-326) set up for resaw with a 1/2″ Woodslicer blade and its working great, but now I need to cut some curved workpieces. I only need to do a couple and then I would want to go back to the setup for resaw.

I dread having to change the blade and set the guides for 1 cut, and then again for resaw, but I also don’t want to distort or dull my resaw blade.

Should I just use this blade for both jobs or is there a blade or configuration that works for general purpose to minimize the changing blades and guide setup? Dan

2) I have a question regarding drawer slides: I am just getting into cabinet making and am excited to slowly make cabinets for my shop. I am first working on a built-in of sorts in my house as part of a bathroom remodel. The built in faces out into the hallway and the back juts into the bathroom, it creates a nook for the toilet area. I made the carcass and have it installed in the wall so that the bathroom side of the project can continue.

I plan to have two deep drawers on the bottom and then shelves with drawers above. I am a little unsure of how to properly size the drawer slides and would love to hear a discussion from you three on this subject. I ordered 21″ undermount Blum softclose slides last fall when I was planning the project. Now that the carcass is made, the inside depth from front (frameless design) to back is 20 3/4″. I see quite a bit online regarding how to install various drawer slides including different YouTube videos that you guys have but I am having trouble with the beginner step of learning how to size the drawer box and drawer slide properly. Do I buy a slide for the cabinet depth or for what my drawer box will be? I think the next available size down for a Blum slide is 18″, will this be difficult to mount in my deeper carcass? Thanks guys, keep up the great content! Jeremy